Combine the skill of drywall contractors and modern Interior Painting for a inviting home look.

Necessary Tips for Effective Drywall Fixing and Setup Techniques

Efficient drywall repair work and installation calls for a mindful strategy. Recognizing the kinds of drywall and having the right devices is vital. Precise dimensions and proper strategies can significantly influence the end result. Lots of ignore important actions like taping and fining sand, which can make or damage the last look. As jobs proceed, typical difficulties may emerge that need attention. Exploring these suggestions can bring about a much more refined and effective finish.

Understanding Various Kinds of Drywall

Comprehending the different kinds of drywall is vital for any effective repair work or setup job. Drywall, frequently understood as gypsum board, can be found in several ranges tailored for particular applications. Criterion drywall is one of the most widely used kind, suitable for general interior wall surfaces and ceilings. Moisture-resistant drywall, usually eco-friendly in shade, is created for locations susceptible to moisture, such as kitchen areas and washrooms. Fireproof drywall, normally colored pink or purple, is crafted to withstand higher temperature levels and is frequently made use of in garages or near furnaces. Furthermore, soundproof drywall helps in reducing sound transmission, making it ideal for multi-family homes or recording workshops. Specialty drywall, like cement board, is made use of in damp areas like showers or tub surrounds. Recognizing these kinds assists in selecting the right product for each and every job, ensuring durability and effectiveness in repair work or new setups.

Vital Tools for Drywall Repair Service and Installation

Having the right tools is necessary for reliable drywall repair work and installment. A quality utility knife is vital for cutting drywall sheets precisely. A drywall T-square helps assure straight edges, while a taping knife is needed for using joint substance smoothly over joints. Additionally, a drywall saw enables reducing out harmed sections or suitable drywall around components.

For hanging drywall, a power drill with drywall screws is important, as it makes it possible for secure and fast setup. A degree is also essential to validate that the drywall is straight and correctly lined up. Once it has actually dried, a sanding block or post sander is vital for smoothing out joint compound. A determining tape is essential for precise measurements, preventing waste and guaranteeing an appropriate fit. Geared up with these devices, individuals can take on drywall jobs efficiently, causing professional-looking outcomes.

Step-by-Step Guide to Repairing Holes and Cracks

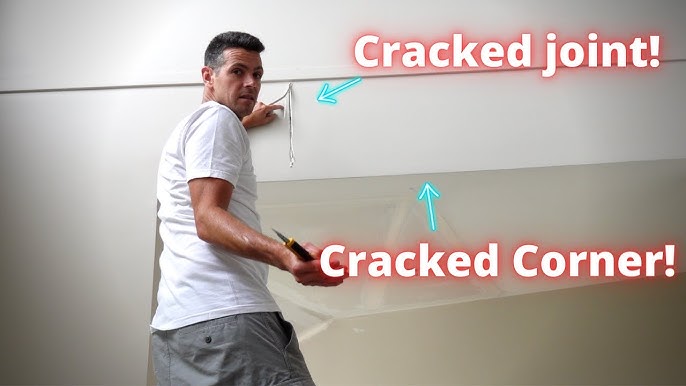

When attending to openings and splits in drywall, having the right tools and products is necessary for an effective repair. This overview details the required things and offers a clear, detailed procedure to efficiently restore the surface area. Understanding these elements will certainly aid assure a seamless finish and lasting results.

Tools and Products Needed

A well-appointed toolkit is essential for effective drywall repair service and installment. Trick devices consist of an energy knife for cutting drywall, a tape action to guarantee precise sizing, and a drywall saw for bigger openings. A putty blade is essential for using joint compound efficiently, while a fining sand block or pole sander helps accomplish a smooth surface. For patching, a roll of fiberglass mesh tape or paper tape is essential to reinforce joints. In addition, a drill and screws are required for securing new drywall pieces. Crucial materials include joint compound, guide, and paint to finish the repair service. Having these devices and products accessible guarantees a smoother, much more efficient fixing procedure, producing professional-looking results.

Repair Service Refine Actions

Fixing holes and fractures in drywall needs an organized technique to ensure a smooth coating. The area bordering the damage should be cleansed thoroughly to remove dirt and particles. Next, for small fractures, a putty knife is made use of to apply a joint substance uniformly over the location. For bigger holes, a patch is essential; the harmed section is eliminated, and a brand-new piece of drywall is suited location, safeguarded with screws. Once the spot is in position, joint compound is put on blend the edges. After drying out, sanding the location smooth is vital. The fixed surface area should be primed and painted to match the bordering wall surface, making certain an inconspicuous repair.

Techniques for Setting Up Drywall Panels

Mounting drywall panels needs careful preparation and accurate implementation to ensure a professional and smooth coating. It is crucial to measure the wall surface area accurately and cut the panels to fit, making certain that they align with the studs. Placing the panels horizontally is typically suggested, as this can improve the structural honesty and reduce the variety of joints.

Making use of drywall screws, installers ought to secure the panels every 16 inches along the studs, ensuring a firm hold. It is essential to avoid overdriving the screws, which can damage the paper surface. For edges and sides, making use of an utility blade enables clean cuts and a snug fit.

Ending Up Touches: Taping, Mudding, and Sanding

When the drywall panels are securely in position, the next important step entails the complements of taping, mudding, and sanding. Taping is essential for developing a smooth change between panels and hiding joints. A top quality drywall tape, either paper or fiberglass harmonize, should be used over the joints, guaranteeing it adheres properly to the mud that will certainly be applied following.

Mudding, or using joint compound, adheres to the taping procedure. This substance fills gaps and smooths out the surface area. An initial coat ought to be used generously, feathering the edges to blend with the drywall. After the initial layer dries, subsequent layers might be required for a remarkable coating.

Sanding is required to attain a smooth surface. A fine-grit sandpaper needs to be used to gently ravel any flaws. Care must be taken to avoid over-sanding, which can damage the drywall - Drywall Installation Ogden Utah. Properly implemented, these ending up touches create an expert look all set for paint

Tips for Preserving Your Drywall After Installation

Maintaining drywall after installment is important to maintaining its appearance and architectural honesty. Normal cleaning is required; dirt and dirt can collect, so gentle wiping with a damp towel is recommended. House owners should also examine for any kind of indicators of wetness or mold and mildew, particularly in high-humidity areas like washrooms and cooking areas. If any kind of damages happens, it is essential to address it quickly to avoid further concerns.

Using furnishings pads can help avoid scrapes or dents from hefty things. Furthermore, painting the drywall with a top quality, washable paint gives an added layer of protection and makes future cleaning easier. Prevent making use of unpleasant cleansers or tools, as these can damage the surface area. Keeping a stable interior environment with proper moisture levels will certainly aid protect against splitting or buckling over time. By following these suggestions, one can guarantee that drywall stays in superb problem for years to come.

Regularly Asked Questions

For How Long Does Drywall Take to Fully Dry After Setup?

Can I Install Drywall Over Existing Drywall?

Yes, drywall can be installed over existing drywall, however it is important to assure the underlying surface area is safe and adequately prepared. This technique can improve insulation and lower setup time, though it might include weight.

What Is the very best Method to Soundproof Drywall?

The very best way to soundproof drywall entails utilizing specialized soundproofing materials, such as durable networks, acoustic caulk, and sound-dampening drywall. These methods efficiently decrease audio transmission between rooms, boosting overall acoustic performance in living areas.

Just how Do I Select the Right Drywall Thickness?

To choose the best drywall density, think about the application and location. Requirement household wall surfaces normally utilize 1/2 inch, while ceilings or specialized areas may require 5/8 inch for extra strength and soundproofing capacities.

Exist Eco-Friendly Drywall Options Available?

Yes, environmentally friendly drywall options are offered. These include products made from recycled products, plaster boards with reduced unstable natural substances (VOCs), and those utilizing lasting production procedures, supplying environmentally-conscious choices for construction and remodelling tasks.

Having the right tools is crucial for reliable drywall repair and installment. For hanging drywall, a click here power drill with drywall screws is vital, as it enables safe and secure and quick setup. Key tools include an energy knife for reducing drywall, a tape action to assure accurate sizing, and a drywall saw for larger holes. Yes, drywall can be installed over existing drywall, but it is vital to ensure the underlying surface area is protected and sufficiently prepared. The ideal means to soundproof drywall involves utilizing specialized soundproofing products, such as resilient networks, acoustic caulk, and sound-dampening drywall.